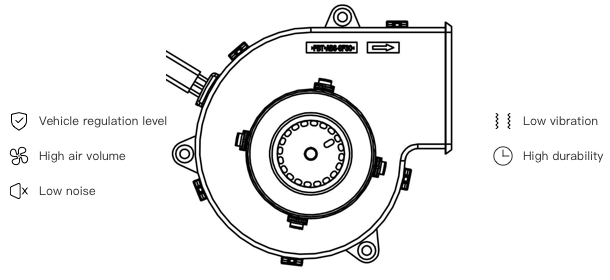

As the core component of the seat comfort system, MYLEE blower uses the latest high-end eddy current technology for car seats. This technology has been widely used by car manufacturers pursuing higher quality and performance. The blower is independently designed by the company's professional team, using three-phase motor built-in general effect silent impeller, which greatly improves the seat ventilation performance and ventilation volume, reduces motor noise and overall noise, and lower vibration, the installation structure is more flexible, good EMC performance, meeting the technical requirements of automotive electronics.

While paying attention to performance, MYLEE strives for excellence in the material selection process to ensure reliability and safety, with a service life of more than 50,000 hours, and strives to zero customer complaints.

As people and automobile manufacturers continue to increase their requirements for ventilation and cooling, and subsequently have higher requirements for noise, ventilation volume, size and EMC, MYLEE will continue to climb the peak in technology.

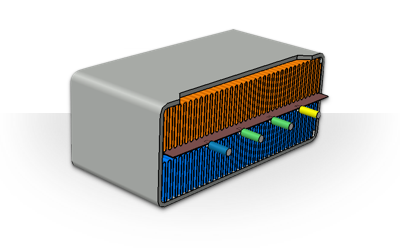

The thermoelectric conversion technology Peltier effect adopted by MYLEE's air-conditioner seat system, which directly converts between heat and electricity, is in line with environmentally friendly green energy technology.

The thermoelectric device material is semiconductor polysilicon, which is a non-combustible material, and there is no safety risk in itself. The cooling effect is very good: the maximum temperature difference can reach about 70 degrees, especially suitable for local cooling and cooling in a small space; it can achieve precise temperature control, using a closed-loop temperature control circuit, the accuracy can reach + -0.1℃; high reliability, The components of refrigeration are solid devices and there are no moving parts, so the failure rate is low; the service life is long, and the service life is more than 200,000 hours; silent, unlike the mechanical refrigeration system, no noise is generated when it is working.

In accordance with the development requirements of the OEM market seating system, MYLEE jointly develops semiconductor modules with core partners on the basis of high-spec design, and is different from the conventional market. MYLEE uses high-purity polysilicon materials to increase the power of the module density and energy efficiency, to achieve real active cooling and heating, and to achieve customization in different applications, strictly implement production processes and quality specifications, to ensure that each semiconductor module is stable and reliable.

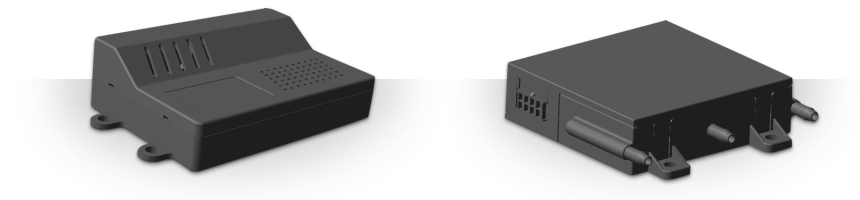

The comfort seat system of MYLEE uses intelligent controllers to coordinate all comfort function components to create the best flexible environment for customers to maximize cabin comfort. Without affecting the installation and cost-effectiveness, MYLEE utilizes rich structural design experience and capabilities, combined with our diverse functional components, to meet customers' various requirements for comfort. The rich functional product library includes active cooling modules, active heating modules, air cooling modules, pneumatic / mechanical massage modules and lumbar support modules. We provide flexible custom designs and complete system solutions.

MYLEE provides customers with customized solutions in strict accordance with the development requirements of the OEM seat market. In order to ensure the high reliability of the system, we integrated an active fault detection module inside the main controller, which can monitor the status of the product in real time and ensure that the system can be in a safe state under the fault / abnormal.